Why Do Low-Voltage Cables Need to Avoid Squeezing? Key Details Related to Electrical Safety

2025-12-26 From: Tianjin Huben Cable Co., Ltd. Browsing times:2

In home decoration wiring, commercial premises circuit renovation, and industrial low-voltage power supply system construction, the laying and protection of low-voltage cables often focus on core indicators such as cross-sectional area selection and insulation performance, but it is easy to ignore the detailed problem of "squeezing". Many construction personnel, for the sake of convenience, randomly squeeze cables during wiring, force cables into conduits, or pile heavy objects on the cable laying path; some users may inadvertently squeeze the cables buried in walls or floors during later decoration and furniture placement. Little do they know that long-term or severe squeezing of low-voltage cables will cause a series of potential safety hazards, directly threatening electrical safety and power supply stability. This article will deeply analyze the core reasons why low-voltage cables need to avoid squeezing, the specific hazards caused by squeezing, and anti-squeezing protection measures in different scenarios, providing practical references for construction personnel and ordinary users.

I. Core Reason: Squeezing Damages Cable Structure and Loses Protection and Transmission Functions

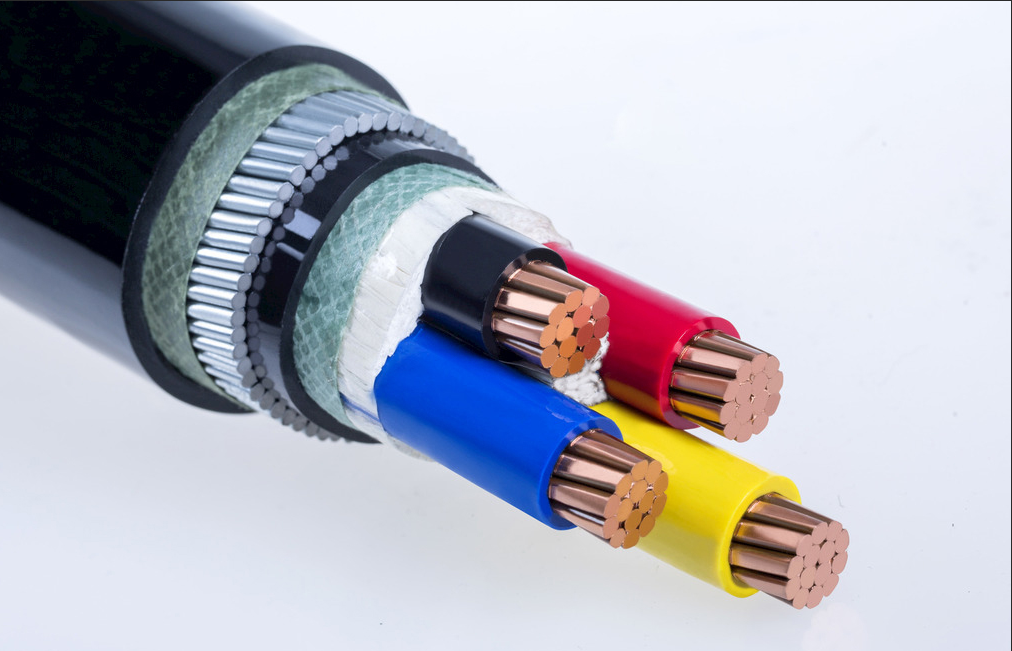

The structure of low-voltage cables from the inside out is conductor, insulation layer, and sheath (some cables include a shielding layer). Each structural layer has its own function: the conductor is responsible for power transmission, the insulation layer isolates current and prevents leakage, and the sheath protects the internal structure from external environmental damage. The design strength and structural stability of the cable are the basis for ensuring its normal operation, and squeezing will directly destroy this balance.

Whether it is long-term external squeezing or instantaneous violent squeezing, it will cause structural damage such as deformation of internal conductors, damage to insulation layers, and cracking of sheaths. When the structural integrity is destroyed, the insulation protection function and power transmission function of the cable will decline simultaneously, leading to faults such as leakage and short circuits. It is particularly important to note that the squeezing damage of cables in concealed scenarios such as wall embedding and pipe threading may have no obvious signs initially, but will gradually deteriorate during long-term use, becoming a potential safety hazard.

II. 4 Specific Hazards of Squeezing, Each Related to Safety

After low-voltage cables are squeezed, the hazards are not limited to the cables themselves, but also spread to the entire power supply system, bringing multiple threats to electrical safety. The specific manifestations are as follows:

1. Insulation Layer Damage, Causing Leakage and Electric Shock Accidents

The insulation layer is the "safety barrier" of low-voltage cables. Its material is mostly insulating materials such as PVC and XLPE, which have limited ability to withstand squeezing. When the cable is excessively squeezed, the insulation layer will crack, dent, or even directly break due to mechanical stress, leading to exposure of internal conductors. When the exposed conductor contacts the outside world (such as walls, metal components, and human bodies), it will cause leakage accidents. If the human body comes into contact with the leaking cable or connected electrical appliances, electric shock injury is likely to occur; for cables in humid environments (such as bathrooms and kitchens), insulation damage caused by squeezing will further increase the leakage risk, with more serious consequences.

2. Conductor Deformation, Leading to Overload Heating and Even Fire

The conductor is the core of power transmission in the cable, mostly copper core or aluminum core, and its cross-sectional area directly determines the current-carrying capacity. When the cable is severely squeezed, the internal conductor may be flattened, deformed, or even have a local reduction in cross-sectional area. According to electrical principles, the reduction of conductor cross-sectional area will lead to an increase in resistance, and the heat generated when current passes through will increase significantly (i.e., "overload heating"). If the heat cannot be dissipated in time, it will accelerate the aging and carbonization of the surrounding insulation layer, and then cause conductor short circuit, generate electric sparks, ignite surrounding combustibles (such as wall fillers and decorative materials), and finally lead to fire accidents. According to fire statistics, cable squeezing damage in concealed projects is one of the important causes of electrical fires in homes and commercial premises.

3. Deterioration of Transmission Performance, Affecting Normal Operation of Equipment

Conductor deformation and poor contact caused by cable squeezing will lead to increased voltage drop and reduced transmission efficiency during power transmission. In household electricity scenarios, excessive voltage drop will cause high-power electrical appliances such as air conditioners and electric water heaters to have difficulty starting, reduced power, or even fail to work normally; for precision equipment in commercial premises (such as computers, printers, and automation equipment), unstable power transmission will cause equipment crashes, data loss, or affect equipment accuracy, resulting in economic losses. In addition, squeezing may also damage the cable's shielding layer (if any), leading to signal interference and affecting the normal operation of weak current systems (such as network cables and monitoring cables).

4. Shorten Cable Service Life and Increase Maintenance Costs

Even if cable squeezing does not cause immediate faults, it will cause irreversible damage to its service life. Microcracks in the insulation layer and stress damage to the conductor caused by squeezing will accelerate the aging process of the cable: microcracks in the insulation layer will make it easier for water vapor and impurities to invade, causing internal corrosion; stress damage to the conductor will reduce its conductivity and further increase the risk of heating. The design service life of ordinary low-voltage cables is about 15-20 years. If they are in a squeezed state for a long time, the service life may be shortened to 5-10 years. The replacement of cables in concealed scenarios requires wall chiseling and floor demolition, which is difficult and costly, bringing unnecessary economic burdens to users.

III. Easily Ignored Squeezing Scenarios, Early Avoidance Is Key

Squeezing damage to low-voltage cables mostly occurs in the details of construction and daily use. The following easily ignored scenarios need to be focused on avoiding:

Construction and wiring stage: Forcing cables into conduits during pipe threading, causing cables to be squeezed inside the pipes; piling too many cables during bridge laying, resulting in mutual squeezing; buried wall cables not protected by pipes, directly squeezed by wall cement and bricks

Later decoration and renovation: Accidentally chiseling or smashing buried wall cables during secondary decoration; not protecting ground wiring, being crushed by decoration materials or heavy equipment;

Daily use process: Furniture is directly placed on the cable path on the ground or wall; heavy objects are piled on the cable laying area in commercial premises; cables in home kitchens and bathrooms are squeezed by cabinets and sanitary .

IV. Anti-Squeezing Measures for Scenarios, Scientific Protection Ensures Safety

Targeted protection measures need to be taken for squeezing risks in different scenarios to avoid squeezing damage throughout the entire process from construction to use:

1. Construction Stage: Standardize Operations to Avoid Squeezing from the Source

Reasonably select conduit specifications: When laying through pipes, the inner diameter of the conduit should not be less than 1.5 times the outer diameter of the cable, ensuring that the cable has sufficient movement space inside the pipe to avoid forced squeezing;

Control the number of cables in the bridge: When laying on the bridge, the cable filling rate should not exceed 40% of the cross-sectional area of the bridge, avoiding mutual squeezing of cables affecting heat dissipation and structural stability;

Strengthen concealed protection: Buried wall and underground cables must be protected by pipes or wire troughs to avoid direct contact with cement and sand; the depth of wall grooves should be sufficient, and the cables should be smoothly filled with mortar after laying to avoid hollow squeezing;

Standardize bending operations: When bending the cable, the minimum bending radius requirement must be followed (the bending radius of copper core cables is generally not less than 6-8 times the cable diameter), avoiding excessive bending leading to internal structural squeezing damage.

2. Daily Use and Maintenance: Grasp Details to Avoid Later Squeezing

Mark cable paths: After the completion of decoration, record and mark the cable paths buried in the wall and ground to avoid accidental squeezing of cables during secondary decoration;

Reasonably place heavy objects: Avoid cable paths when placing furniture and equipment; clearly mark cable positions in the goods stacking area of commercial premises to avoid long-term heavy pressure;

Regular inspection and troubleshooting: Regularly check whether exposed cables have signs of squeezing and deformation; for concealed cables, if cracks are found on the surrounding walls and floors, or electrical appliances have abnormal heating, tripping and other conditions, it is necessary to timely check whether there is cable squeezing damage.

Related Articles More>>

- What Are the Common Faults of Low-Voltage Cables and How to Troubleshoot Them Quickly?

- How to Prevent Corrosion of PV Cables in Humid Environments? Practical Protection Guide

- How to Make High-Voltage Cable Intermediate Joints More Reliable? Full-Process Specifications + Quality Control Points

- How to Quickly Repair Damaged Insulation Layer of High-Voltage Cables? Full-Process Guide + Safety Points