How to Prevent Corrosion of PV Cables in Humid Environments? Practical Protection Guide

2025-12-26 From: Tianjin Huben Cable Co., Ltd. Browsing times:2

PV power plants are constructed in diverse scenarios, and high-humidity environments are common in areas such as coastal regions, lakesides, rainy areas, and basements. Water vapor, salt, acid-base substances, etc. in humid environments will continuously corrode PV cables, leading to aging of cable insulation layers, damage to sheaths, and corrosion of conductors. This further causes faults such as short circuits and leakage, seriously affecting the safe and stable operation and power generation efficiency of the power plant. Therefore, doing a good job in corrosion prevention of PV cables in humid environments is a key link in the construction and operation and maintenance of PV power plants. This article will deeply analyze the corrosion mechanism and hazards of PV cables in humid environments, provide a full-process corrosion prevention solution covering selection, laying, and operation and maintenance, and offer practical references for the construction of PV power plants in humid areas.

I. First, Understand: The Corrosion Mechanism of PV Cables in Humid Environments

The corrosion of PV cables in humid environments is not a single effect, but the result of long-term reactions between water vapor, corrosive media, and cable materials, mainly reflected in three aspects:

First, water vapor penetration and erosion. Water vapor in humid environments will penetrate into the interior through tiny pores of the cable insulation layer and sheath, causing moisture aging of the insulation layer, a significant decline in insulation performance, and simultaneous oxidation and corrosion of conductors. Especially in scenarios with large temperature differences, water vapor is likely to condense into water droplets, directly adhering to the surface and interior of the cable, accelerating the corrosion process.

Second, chemical corrosion. The humid air in coastal and salt spray areas contains a lot of salt, and rainwater in rainy areas may carry acid-base substances. These corrosive media will chemically react with the cable sheath and insulation layer materials, destroying the material structure and leading to cracking of the sheath and chalking of the insulation layer. For conductors, salt and acid-base substances will accelerate the oxidation of copper conductors, forming a corrosion layer, increasing conductor resistance, and affecting power transmission efficiency.

Third, electrochemical corrosion. The humid environment provides the necessary electrolyte environment for electrochemical corrosion. The cable conductor, sheath, and impurities in the environment form a micro-battery, resulting in redox reactions. Among them, the conductor, as the anode, will be gradually corroded and consumed, eventually leading to a reduction in the cross-sectional area of the conductor, or even breakage, causing interruption of power transmission.

II. Be Alert to Hazards: 3 Major Impacts of Humid Corrosion on PV Power Plants

After PV cables are corroded in humid environments, they will not only shorten the service life of the cables themselves but also bring a series of safety and economic hazards to the PV power plant:

Frequent power transmission faults: After the cable insulation layer is damp and aging, leakage and short-circuit faults are likely to occur, resulting in the failure of normal transmission of power generated by PV modules. Core equipment such as inverters and combiner boxes frequently alarm and shut down, significantly reducing the power generation efficiency of the power plant;

- Increased equipment damage and maintenance costs: Short-circuit faults may directly damage equipment such as inverters and fuses. At the same time, corroded cables need to be replaced in a timely manner. Construction in humid environments is difficult, further increasing maintenance costs and downtime losses;

Hidden safety hazards: Leakage faults will threaten the personal safety of operation and maintenance personnel, and may even cause fires in severe cases, resulting in property losses of the power plant.

III. Full-Process Protection: Corrosion Prevention Solutions for PV Cables in Humid Environments

In view of the corrosion characteristics of humid environments, the corrosion prevention of PV cables should follow the principle of "source control, process protection, and regular maintenance", and build a full-process protection system from three core links: selection, laying, and operation and maintenance.

1. Selection: Prioritize the Use of Special PV Cables Resistant to Humidity and Corrosion

Selection is the basis of corrosion prevention. It is necessary to focus on core indicators such as cable materials and protection levels to improve the corrosion resistance of cables from the source:

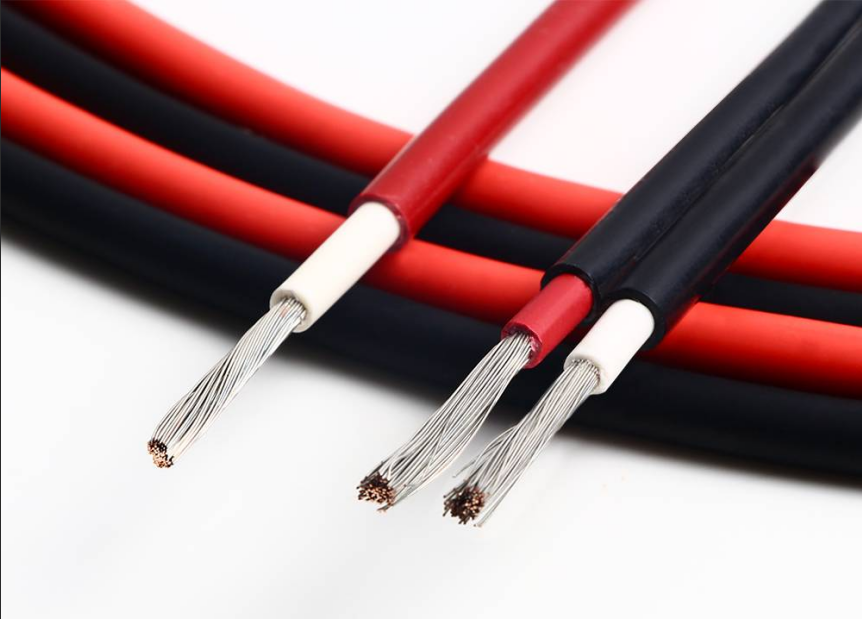

- Prefer corrosion-resistant materials: For the sheath and insulation layer, prioritize materials resistant to humidity, salt spray, and acid-base, such as cross-linked polyethylene (XLPE), fluoroplastics (PTFE, FEP), and weather-resistant PVC, avoiding ordinary material cables. Among them, fluoroplastic cables have the best corrosion resistance, suitable for extreme humid and corrosive environments such as coastal areas and salt spray areas;

Pay attention to protection level: Select PV cables with a protection level of ≥IP67 to ensure that the cables have good waterproof and dustproof performance and reduce the intrusion of water vapor and impurities;

- Confirm standard compliance: Prioritize the use of PV-specific cables that meet the national standard GB/T 12706.1-2022 and international standard IEC 60228. Check the product's damp-heat resistance and salt spray resistance test reports to ensure that its corrosion environment adaptability meets the standards.

2. Laying: Standardize Construction and Build a Physical Protection Barrier

A reasonable laying method can effectively isolate the direct contact between the humid environment and the cable, reducing the risk of corrosion. The following key points should be noted during construction:

- Avoid waterlogged areas: The cable laying path should avoid low-lying waterlogged areas, drainage ditches, and other high-humidity disaster areas, and try to choose higher-lying, well-ventilated and dry areas;

Adopt protective sleeves and cable trays: In humid environments, cables need to be laid through corrosion-resistant PVC pipes, stainless steel pipes, or FRP cable trays to avoid direct exposure of cables to humid air. When laying through pipes, the pipe joints should be properly sealed to prevent water vapor from entering; when laying on cable trays, it is necessary to regularly clean up water accumulation and debris in the cable trays;- Ensure joint sealing: Cable joints are weak links in waterproofing and corrosion prevention. Special waterproof and corrosion-resistant joints (such as cold-shrink waterproof joints and heat-shrink waterproof joints) should be selected. During construction, handle them in strict accordance with operating specifications to ensure tight sealing of the joints. The joint position should avoid humid areas as much as possible, and a waterproof junction box should be installed if necessary;- Control the laying slope: A certain slope should be reserved when laying cables to avoid water accumulation at the lowest point of the cable, ensuring that water vapor can be discharged smoothly and reducing water vapor accumulation and erosion.

3. Operation and Maintenance: Regular Inspection to Timely Handle Corrosion Hidden Dangers

In humid environments, the corrosion of PV cables is a gradual process. Regular operation and maintenance can timely find and handle hidden dangers, extending the service life of cables:

Regular appearance inspection: Conduct an appearance inspection of the cables at least once a month, focusing on checking whether the cable sheath has corrosion signs such as cracking, bulging, chalking, and discoloration, and whether the joints have water seepage and corrosion traces. For coastal and salt spray areas, the inspection frequency should be increased;

Timely cleaning and drying: Regularly clean up water accumulation, oil stains, salt frost, and other impurities on the cable surface to keep the cable surface dry and clean. If the cable is found to be damp, wipe it clean with a dry cloth in a timely manner, and use hot air drying if necessary;

Insulation performance testing: Conduct an insulation resistance test on the cables every six months to one year, using a 500V megohmmeter. If the test value is lower than 0.5MΩ, it indicates that the cable insulation layer has been damp and aging and needs to be replaced in a timely manner;

Timely replacement of damaged cables: When obvious corrosion, insulation layer damage, and other problems are found in the cables, it is necessary to shut down the machine immediately to replace the damaged cable section to avoid expanding the fault. When replacing, select special corrosion-resistant cables of the same specification to ensure consistent protection performance.

IV. Enhanced Protection for Special Scenarios: Targeted Measures for Coastal Areas/Basements

Different humid scenarios have different corrosion characteristics, and targeted enhanced protection measures need to be taken:

Coastal salt spray environment: Prioritize the use of fluoroplastic PV cables. During laying, use stainless steel sleeves or FRP cable trays, and install salt spray-proof sealing boxes at the joints. Regularly clean the cable surface with salt spray to reduce salt adhesion;

Basement humid environment: Focus on ventilation and dehumidification, and install dehumidification equipment to reduce environmental humidity. Cables are laid through pipes, the entire pipeline is sealed, and IP68 joints with higher waterproof level are selected at the joints to avoid water vapor intrusion.

Related Articles More>>

- How to Quickly Repair Damaged Insulation Layer of High-Voltage Cables? Full-Process Guide + Safety Points

- How to Make High-Voltage Cable Intermediate Joints More Reliable? Full-Process Specifications + Quality Control Points

- Will PV Cables Become Brittle in Low-Temperature Environments? Complete Analysis of Answers and Solutions

- What Key Details Need to Be Noticed During the Installation of High-Voltage Cables? Avoid These Pitfalls to Ensure Power Supply Safety!high-voltage cable