How to Quickly Repair Damaged Insulation Layer of High-Voltage Cables? Full-Process Guide + Safety Points

2025-12-26 From: Tianjin Huben Cable Co., Ltd. Browsing times:2

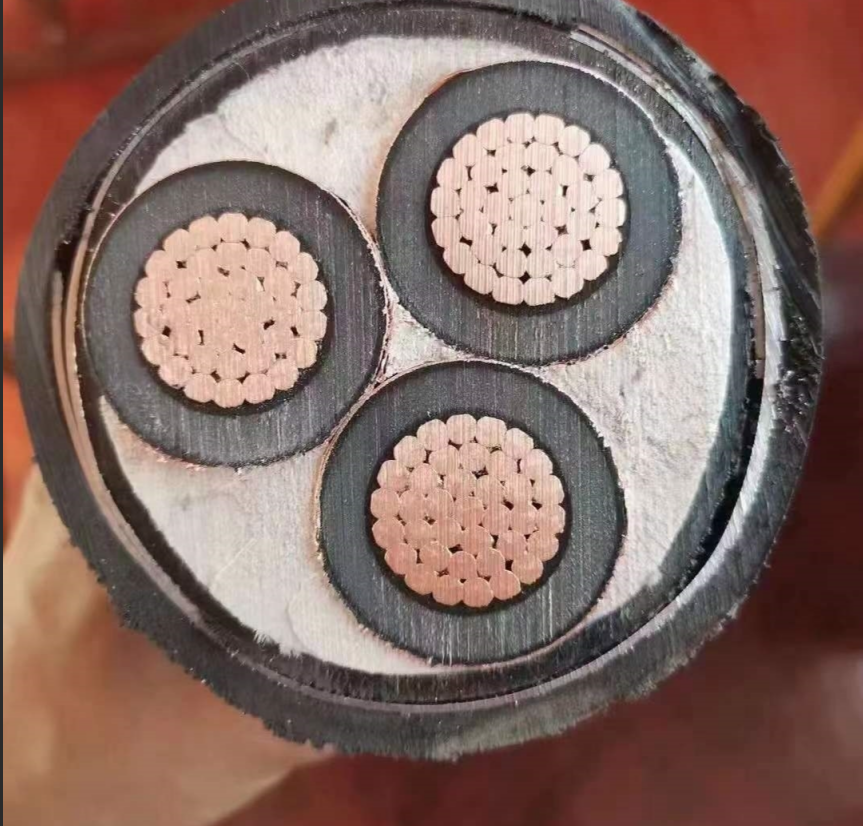

The insulation layer of high-

voltage cables is the "protective barrier" ensuring safe power transmission. Once damaged, it is prone to causing faults such as insulation breakdown, short circuits, and electric leakage, and even inducing safety accidents like fires and electric shocks, seriously affecting the stable operation of the power grid. In practical production and life, cable laying friction, mechanical collision, environmental corrosion, aging and cracking may all lead to insulation layer damage. Faced with sudden insulation layer damage, how to complete the repair quickly and efficiently, minimize power outage time and economic losses? Combining industry practical experience, this article provides a actionable quick repair guide from the dimensions of damage assessment, scenario-specific repair methods, operation specifications, and safety points, helping relevant practitioners handle the problem accurately.

I. First, Clarify: Hazards of Insulation Layer Damage and Emergency Disposal Principles

After the insulation layer of high-voltage cables is damaged, if not handled in time, the damaged part will gradually expand due to long-term exposure to high voltage and humid environment erosion, leading to a sharp decline in insulation performance. Mild damage may cause partial discharge and increased power loss; severe damage will cause inter-phase short circuits of cables, leading to large-area power outages, and even damage power equipment and threaten the personal safety of operation and maintenance personnel.

Faced with insulation layer damage, it is necessary to follow the emergency disposal principles of "first assess, then cut off power, select the right method, and standardize operation": first, judge the damage degree and environmental conditions, and it is strictly prohibited to directly touch the damaged part without cutting off power; second, immediately start the temporary power outage plan and set up safety warning signs; finally, select an appropriate repair plan according to the damage type to ensure that the insulation performance after repair meets the standards and avoid "treating the symptoms but not the root cause".

II. Key Pre-Repair Steps: Damage Assessment and Preparation Work

The premise of quick repair is to accurately assess the damage situation and make full preparation work to avoid repair failure or secondary damage due to insufficient preparation.

1. Comprehensive Assessment of Damage Situation

Operation and maintenance personnel need to carry tools such as insulating gloves, voltage testers, megohmmeters, and tape measures, and conduct the following assessments after confirming that the cable is completely powered off and grounded:

Damage Degree: Measure the length and depth of the damaged part to judge whether the conductor or armor layer is damaged. It is divided into mild damage (only the surface of the insulation layer is scratched, depth ≤1mm, length ≤50mm, and the semi-conductive layer is not damaged), moderate damage (insulation layer damage depth >1mm but not penetrating, length 50-200mm, semi-conductive layer may be damaged), and severe damage (insulation layer penetrating, conductor exposed or armor layer damaged, damage length >200mm).

Damage Environment: Confirm whether the damaged location is in indoor cable tray, outdoor direct burial, pipe laying or humid water accumulation environment.environments have different requirements on the waterproof and corrosion-resistant performance of repair materials.

Insulation Performance Test: Use a megohmmeter to measure the insulation resistance before and after the damaged part of the cable. The insulation resistance of 10kV cables should be ≥1000MΩ, and that of 35kV cables should be ≥2500MΩ. If the insulation resistance drops significantly, further investigate whether there is hidden damage.

2. Pre-Repair Preparation Work

Safety Protection Preparation: Equip with protective equipment such as insulating gloves, insulating boots, safety helmets, voltage testers, and grounding wires. Set up warning signs of "High Voltage Danger, No Entry" in the construction area, arrange special personnel for on-site supervision, and prohibit irrelevant personnel from entering.

Tool and Material Preparation: Prepare corresponding repair materials according to the damage degree. Core materials include insulating self-adhesive tape, cold-shrink insulating sleeve, heat-shrink insulating sleeve, insulating filling glue, semi-conductive tape, etc.; tools include stripping knife, sandpaper, cleaning cloth, hot air (special for heat shrinkage), crimping pliers, etc. All tools must pass insulation testing.

- On-site Cleaning: Clean the dust, oil stain and accumulated water around the damaged part, gently polish the surface of the damaged part and the surrounding insulation layer with sandpaper to keep it dry, clean and free of burrs, and enhance the adhesion between the repair material and the insulation layer.

III. Scenario-Specific Quick Repair Methods: Adapting to Damage Degrees and Environments

According to the differences in the damage degree of the insulation layer and the environment, different repair plans need to be selected to ensure both repair efficiency and effect. The following are the detailed operation processes of three mainstream repair methods:

1. Mild Damage: Insulating Self-Adhesive Tape Winding Repair Method (Quick Emergency)

Suitable for temporary or permanent repair of mild damage in dry indoor environment. It is simple to operate, time-consuming, and can be completed by a single person. The repair time is about 15-20 minutes.

Operation Steps:

1. Cleaning and Polishing: Wipe the damaged part and the surrounding 5-10cm insulation layer with a cleaning cloth, then gently polish the surface with sandpaper to remove the oxide layer and impurities, and finally wipe it clean again with a cleaning cloth.

2. Winding Primer: Use butyl rubber insulating self-adhesive tape as the, start winding from one end of the damaged part. Keep the tape stretched by 20%-30% during winding, and the overlapping width is 1/2 of the tape width. Ensure that the damaged part and the surrounding 2-3cm area are completely covered, and wind 2-3 layers to form the basic insulation layer.

3. Reinforced Insulation: Wind high-voltage insulating self-adhesive tape on the outer layer of the . The winding method is the same as that of the , with moderate stretching force, and wind 3-4 layers to ensure that the insulation thickness is not less than the original insulation layer thickness.

4. Sealing Protection: If there is slight humidity in the environment, wind a layer of waterproof insulating tape on the outermost layer, wind it tightly, and the two ends exceed the inner insulating tape by 2cm to complete the sealing.

Note Points: Keep the tape flat without bubbles or wrinkles during winding; after repair, press the tape by hand to ensure that it is closely attached to the insulation layer without loosening.

2. Moderate Damage: Cold-Shrink Insulating Sleeve Repair Method (Universal and Efficient)

Suitable for permanent repair of moderate damage in various indoor and outdoor environments (including humid and dusty environments). The cold-shrink sleeve shrinks and fits the cable relying on its own elasticity, no heating is required, the operation is convenient, the sealing performance is good, and the repair time is about 30-40 minutes.

Operation Steps:

1. Pretreatment of Damaged Part: Clean and polish the damaged part and the surrounding 10-15cm insulation layer. If the semi-conductive layer is damaged, trim the semi-conductive layer with a special stripping knife to ensure that the transition between the semi-conductive layer and the insulation layer is flat without burrs.

2. Selecting Sleeve: Select a cold-shrink insulating sleeve matching the outer diameter of the cable. The length of the sleeve should cover 5-8cm at both ends of the damaged part to ensure that the damaged area is completely wrapped.

3. Sleeve Installation: Put the cold-shrink sleeve into the cable, move it to the central position of the damaged part, first tear off the release rope at one end of the sleeve, let the sleeve shrink and fit the cable under the action of elasticity, then slowly tear off the release rope at the other end to ensure that the sleeve shrinks evenly as a whole without bubbles or gaps.

4. Filling and Sealing: If there are depressions or gaps at the damaged part, fill an appropriate amount of insulating filling glue at the damaged part before putting in the sleeve to enhance the insulation and sealing effect; after the sleeve shrinks, press both ends of the sleeve by hand to ensure firm sealing.

Note Points: Once the cold-shrink sleeve shrinks, it cannot be reused, so accurate positioning is required before installation; it is forbidden to pull or twist the sleeve during the shrinkage process of the sleeve to avoid affecting the adhesion.

3. Severe Damage: Heat-Shrink Insulating Sleeve + Semi-Conductive Layer Repair Method (Thorough and Durable)

Suitable for permanent repair of severe damage with penetrating insulation layer, damaged semi-conductive layer or exposed armor layer, as well as harsh environments such as outdoor direct burial and pipe laying. The insulation performance after repair is close to that of the original cable, and the repair time is about 60-90 minutes.

Operation Steps:

1. Trimming of Damaged Part: First, clean the debris at the damaged part, cut off the severely damaged insulation layer with a stripping knife, and trim the conductor surface (if the conductor is damaged, crimp repair is required); then polish the end face of the remaining insulation layer with sandpaper to form a smooth transition surface, and the semi-conductive layer needs to reserve a length of 1-2cm to facilitate subsequent overlapping.

2. Repair of Semi-Conductive Layer: Select a semi-conductive tape matching the original cable, start winding from the reserved end of the semiconductive layer, the overlapping width is 1/2 of the tape width, and wind to the transition surface of the insulation layer to ensure that the connection between the semi-conductive layer and the insulation layer is flat without steps.

3. Insulation Filling and Sleeve Installation: Fill the damaged part with insulating filling glue to ensure that all gaps are filled; select a heat-shrink insulating sleeve of matching specification (length covering 8-10cm at both ends of the damaged part), put it into the cable and position it to the central position of the damaged part, heat evenly from the middle of the sleeve to both ends with a hot air to make the sleeve shrink and fit the cable. During the heating process, move the hot air continuously to avoid local overheating damaging the sleeve.

4. Outer Layer Protection: For direct burial or humid environment, wind a layer of waterproof tape on the outer layer of the heat-shrink sleeve, or install a waterproof seal box to enhance waterproof and corrosion-resistant performance.

Note Points: Control the temperature of the hot air during heating (generally 120-160℃) to avoid aging of the insulation layer due to excessive temperature; after repair, ensure that the semi-conductive layer is continuous and the insulation layer has no bubbles, otherwise partial discharge will be caused.

IV. Must-Do After Repair: Insulation Testing and Acceptance Points

After the repair is completed, strict testing is required to verify the repair effect to ensure that the cable insulation performance meets the standards before restoring power supply and avoiding potential safety hazards. Appearance Acceptance: Check the adhesion of materials at the repair part, no bubbles, wrinkles or loosening; no gaps at the sealing part, and the waterproof tape is tightly wound; the connection between both ends of the sleeve and the cable insulation layer is flat without obvious steps.

Insulation Resistance Test: Use a megohmmeter to measure the insulation resistance before and after the repair part again. The test result should not be lower than the insulation resistance value before repair, and meet the insulation requirements of cables of the corresponding voltage level (10kV≥1000MΩ, 35kV≥2500MΩ).

Withstand Voltage Test: For severe damage repair or important power supply lines, a DC withstand voltage test is required. The test voltage is 3-5 times the rated voltage of the cable, and the duration is 15 minutes. During the period, no breakdown and no obvious fluctuation of leakage current are qualified.

- Power-On Trial Operation: After the test is qualified, remove the grounding wire and restore power supply. During the trial operation of 1-2 hours, closely monitor the cable operation status. No abnormal heating or abnormal noise means the repair is qualified.

V. Key Suggestions for Preventing Insulation Layer Damage

Compared with post-repair, early prevention can more effectively reduce the risk of insulation layer damage:

1. Standardize Laying Construction: Avoid dragging and friction during cable laying. For direct burial laying, a fine sand protective layer should be laid; for pipe laying, the pipe orifice should be chamfered; for cable tray laying, the fixed fixture should be adapted to the outer diameter of the cable to avoid squeezing the insulation layer.

2. Strengthen Daily Inspection: Regularly check the cable laying path, and timely clean up sharp debris and heavy machinery rolling risks; replace aging cables in time to avoid damage due to aging and cracking.

3. Optimize Environmental Protection: In humid, dusty and corrosive environments, select waterproof and corrosion-resistant cables or install protective sleeves; do a good job in sealing and waterproof treatment at outdoor cable joints to avoid rainwater infiltration leading to insulation layer damage.

Related Articles More>>

- What Are the Common Faults of Low-Voltage Cables and How to Troubleshoot Them Quickly?

- Will PV Cables Become Brittle in Low-Temperature Environments? Complete Analysis of Answers and Solutions

- How to Make High-Voltage Cable Intermediate Joints More Reliable? Full-Process Specifications + Quality Control Points

- How to Prevent Corrosion of PV Cables in Humid Environments? Practical Protection Guide